Guaranteed Quality

About Rebuilt Products

At Japan Rebuild, we set our own rigorous quality standards for rebuilt parts, ensuring reliability and performance. Advanced diagnostic machines are used to maintain and verify the highest quality in every product we deliver.

What Japan Rebuilt can do

- Challenging non-disassembled parts

- For parts that are traditionally non-disassemblable, Japan Rebuild takes a unique approach. Using cutting-edge machinery at our in-house facilities, we design and manufacture replacement components to restore functionality to 'like-new' quality. This innovation ensures better performance at a lower cost

- JRC Quality

- Is the quality and functionality of the product reassuring to customers? At Japan Rebuild, we have a long warranty on our products, and we have established high quality standards, and inspections for each process and inspections at the time of completion are We deliver high-quality products by dropping the data accumulated over many years into the latest computer-controlled machines and analyzing them.

- Product Inventory Management

- With a nationwide delivery network and extensive inventory across multiple locations, we ensure rapid shipping and availability of parts whenever you need them

Quality control/quality assurance

AT CVT MT Mission

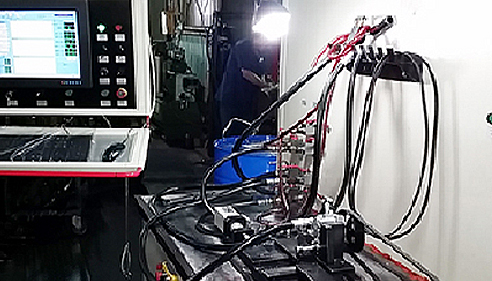

In recent years, vehicles have become more electronically controlled, and even if the mission fails, it is not clear whether it is caused by the mission itself or by the computer. It is difficult to identify, and it is difficult to confirm normal operation with a tester machine that operates the conventional mission alone. In order to accurately understand the operating state inside the mission even in such a vehicle model, we have built the information of the mission computer into the tester machine. The computer diagnoses and determines whether the mission is operating according to the information provided by the computer, and whether the solenoid valve is operating according to the information provided by the computer.

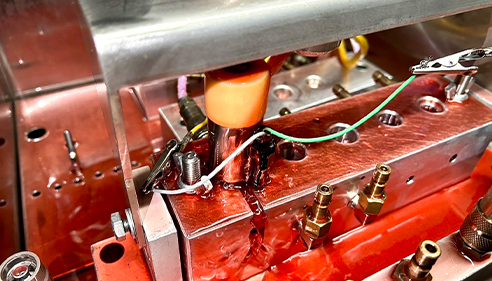

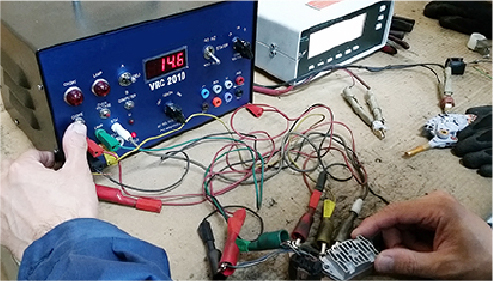

- Solenoid Valves

- We completely disassemble and rebuild solenoid valves of non-disassembled parts at our own factory. By reviving the solenoid valve as good as new with a high-performance tester machine, we can keep the cost down and meet everyone's needs. The rebuilt solenoid valve is hung on the tester machine for each manufacturer to confirm that it is operating according to the information sent from the tester machine.

-

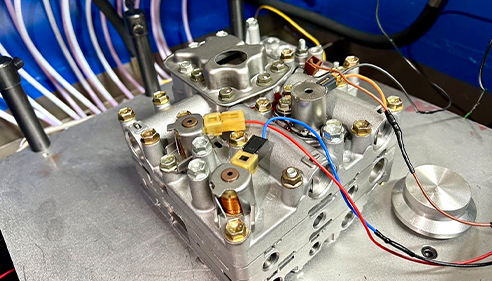

- Valve Body Tester Machine

- The rebuilt solenoid valve is actually mounted on the mission from the mission computer and reproduced the state of running. Test that it is working according to the information from the mission computer.

-

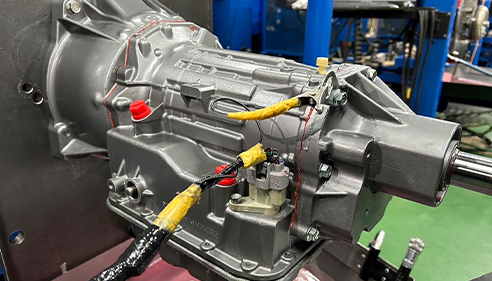

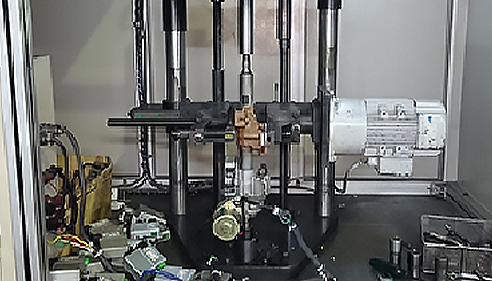

- AT/CVT Mission Tester Machine

- For each vehicle type, the time lag at the gear shift point according to the vehicle speed, accelerator opening, occurrence of shifting shock, hydraulic status, and solenoid operating status can be understood at a glance. The status is fed back to the computer and diagnosed whether it was operating according to the information provided by the computer.

-

- MT Missions

- Our expertise extends across a wide range of manual transmissions (MT), from compact cars to 4-ton trucks. Recently, we've specialized in heavy-duty truck transmissions, including smooth shifting solutions for models like the Isuzu Elf

-

engine

We offer engine rebuilds for a wide range of vehicles, from compact cars to 2-ton trucks, delivering reliable performance and extended lifespan. With a large inventory of commercial vehicles, especially light cargo, we ensure quick delivery. Our engines maintain stable quality through high standards for essential replacement parts, regardless of core condition. Additionally, we perform firing tests to guarantee reliability.

- Honing (boring)

- The cylindrical spindle to which the whetstone is attached presses against the inner diameter of the cylinder bore, reciprocates and rotates while maintaining a constant state of surface contact, and the burrs in the cylinder are removed by polishing the inner diameter. In addition, when an oversized piston is used, boring is performed according to the size of the piston.

-

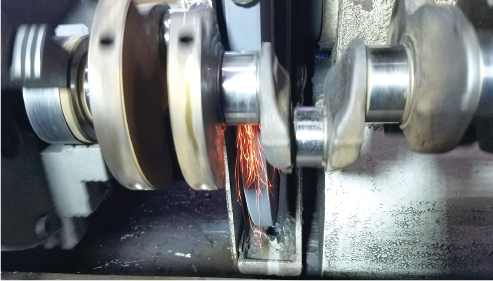

- Crankshaft machining

- All crankshafts are wrapped, but when assembling oversized metal, the crankshaft is polished to undersize.

-

- Engine Tester Machine

- The completed engine is subjected to firing tests with 10 dedicated testers set up by each manufacturer. In the firing test, we will check for cooling water blowback, abnormal noise, oil leakage, cooling water leakage, and inspection of each port, recheck the looseness of bolts, attach gaskets, and ship it in a strictly packed bag.

-

power steering

In recent years, from the viewpoint of manufacturers' emphasis on fuel efficiency, vehicles have shifted to a motor type that does not apply an engine load. Motorized rack and pinion and motorized steering columns are EPS (power steering computer controlled) and require time to develop. We were one of the first to work on motorized racks and pinions and motorized steering columns, and we have developed a tester machine with a built-in computer to increase the number of items. In addition, we have expanded the range of items from conventional hydraulic power steering to mini cars and passenger cars, as well as 2-ton vehicles and large trucks, to meet the needs of our customers.

- Power Steering Vane Pump Tester

- The data on the oil pressure and oil discharge flow rate of each product is input into the tester machine, and the computer diagnoses whether the value of the product reaches the specified value by inspecting it by automation.

-

- Power Steering Rack & Pinion Tester

- Since the oil pressure differs depending on each car model, the oil pressure data for each car model is entered, and the computer diagnoses whether the value of the product is within the specified value by inspecting it by automation.

-

- Motorized rack-and-pinion steering column

- The PS computer of each car model is built into the tester, and the computer diagnoses whether it is operating according to the torque from the computer and feeds back the operation status.

-

Alternators, Starter Motors, AC Compressors

Our rebuilt alternators, starter motors, and AC compressors are consistently disassembled, assembled, and inspected at our own factory. In addition to replacing consumable parts, we also inspect component parts to ensure stable product quality management. We offer a low-cost warranty with a long warranty of 2 years and 20,000 km. We always have 100,000 items in stock, from light vehicles to large trucks, and we respond to your needs with an immediate delivery system.

- Stator Coil Inspection

- A computer built into the measuring machine quantifies the state of insulation and disconnection inside the rotor and coil by applying a high voltage, and determines whether the product is passed or rejected.

-

- IC Regulator Inspection

- The voltage and current control operating status of the IC regulator circuit alone is checked and the pass/fail judgment is made.

-

- Alternator Simulation Test

- Each alternator is thoroughly tested using advanced diagnostic equipment. Performance is evaluated across all RPM ranges, with precise measurements of voltage, current, and internal component functionality. Only products meeting or exceeding our strict standards are approved for shipment.

-

- Starter Motor Simulation Test

- All completed starter motors are inspected for performance with a dedicated tester machine. The reference value of the starter motor is input inside this tester, and the rotation speed of the motor at the specified torque value, the output value, whether the specified voltage is flowing normally in the motor, etc. are measured. We independently diagnose whether the tester machine has cleared the standard value input, and ship the product that passes.

-

- AC Compressor Body Gas Leak Vacuum Inspection

- The completed air conditioner compressor body is first inspected for gas leakage by completely sealing the main body to ensure that there is no gas leakage, and then pressing in nitrogen gas.

-

- AC Compressor Dedicated Tester Machine

- The tester machine is inspected with a tester machine that reproduces the state of being mounted on an actual car, with a built-in condenser, receiver tank, exhaust, and evaporator. The outside temperature is measured, and the state of high pressure and low pressure, the state of liquefaction of gas from high pressure ~ vaporization is projected on the monitor so that it can be understood at a glance. In addition, the tester machine has an air outlet from which you can check the cold air that has actually been cooled.

-

Explore our product catalog or learn more about our rebuilding processes by clicking the link below